Courtesy Reuters.com The whack-a-mole economy: U.S. manufacturers struggle with unpredictable supplies By Timothy Aeppel William Vasquez…

Mauldin’s 1560 Asphalt Paver

Via Asphalt Pro

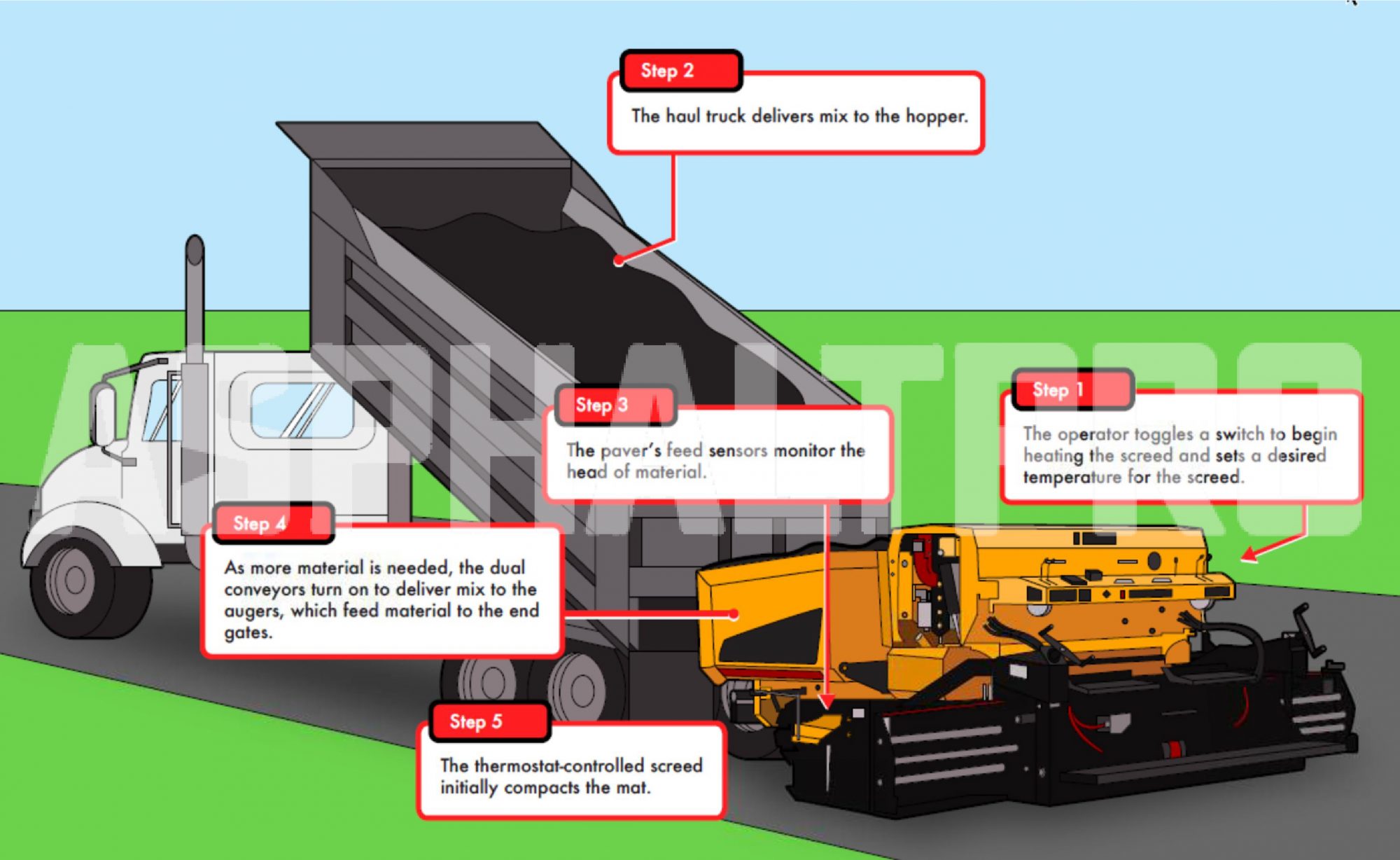

Maintaining the proper temperature on the screed is key to leaving behind a pristine mat. Cold or unevenly-heated screeds are more likely to pick up material and mar the newly laid asphalt mat. That’s why the team at Mauldin, Taylors, South Carolina, built its new 1560 commercial paver with an electrically heated, thermostat-controlled screed. Here’s how the 1560 paver works.

Before paving begins, the operator heats the screed by toggling a switch located next to the paver’s 5-inch color digital display. This display is used to control all gauges, as well as material height and screed temperature. The electrically heated screed draws power from a 14 Kw direct-driven generator mounted directly on the 1560’s Cummins 74 hp engine. The operator then sets a desired temperature for the screed, and in less than 15 minutes, the screed will be at paving temperature.

Next, the haul truck delivers mix to the 1560’s 6.5-ton hopper. The paver’s feed sensors, located on each end gate, actively monitor the head of material. As the sensors indicate that more mix is needed, the 1560’s independent dual conveyors automatically feed material on demand to the augers. The conveyors turn off and on, as needed, to maintain a consistent head of material.

The 1560 has four augers–two main augers mounted on the screed and one auger on each screed extension–to move material out to the end gates. The dual auger system offers extension flexibility from 8 to 14 feet.

The mix then passes under the 1560’s Freedom Fourteen free floating vibratory screed. As the 1560 tracked paver moves forward at speeds up to 140 feet per minute, its 3400-pound screed offers initial compaction of the asphalt mat.

Throughout the job, a thermostat will monitor the screed’s temperature and automatically turn on or off each of the four different heat zones on the screed and two heat zones on the extensions to maintain the temperature set by the operator at the beginning of the job. Each of these heat zones is monitored by one of four temperature sensors. The system automatically detects any faulty sensors and monitors that sensor’s heat zone with the sensor of an adjoining heat zone until the faulty sensor is repaired so paving can continue without downtime.

The 1560 is ideal for paving small roads and parking lots. It was introduced at World of Asphalt 2019 alongside two other new Tier 4 commercial class pavers from Mauldin, the 1860 and 650.

For more information, contact Brandon Granger at brandon.granger@calderbrothers.com or (864) 244-4800.

Learn More on the 1560 Paver here